Every man’s garage needs an air compressor. Whether you are a professional mechanic, or just despise the coin-operated air compressors at the local gas station (or the people there), an air compressor is more than a want, it’s a need.

I like to work on all my gear myself because it helps me learn more about my equipment, and it saves some coin. This extends from doing surgery on a computer to working on a truck. Years ago, I used a friend’s air compressor, and it was a beast. The thing was bulletproof, and it had been chugging for 7+ years. Oil-free, 30-gallon tank, good airflow. It wasn’t until I moved away from that dear compressor that I realized how much I missed it, how much I liked the convenience…how much I needed it.

An air compressor would be mine!

Research

When I first started researching air compressors, I knew exactly what I wanted: the air compressor my friend had. I liked the numbers, it performed great, and I was familiar with its operation. It wasn’t until I went online to find one that I realized it wouldn’t be that easy. My friend had a Craftsman 16731, which apparently doesn’t exist anymore. Even the Sears website says it is ‘temporarily unavailable,’ in which case temporarily means the past few years.

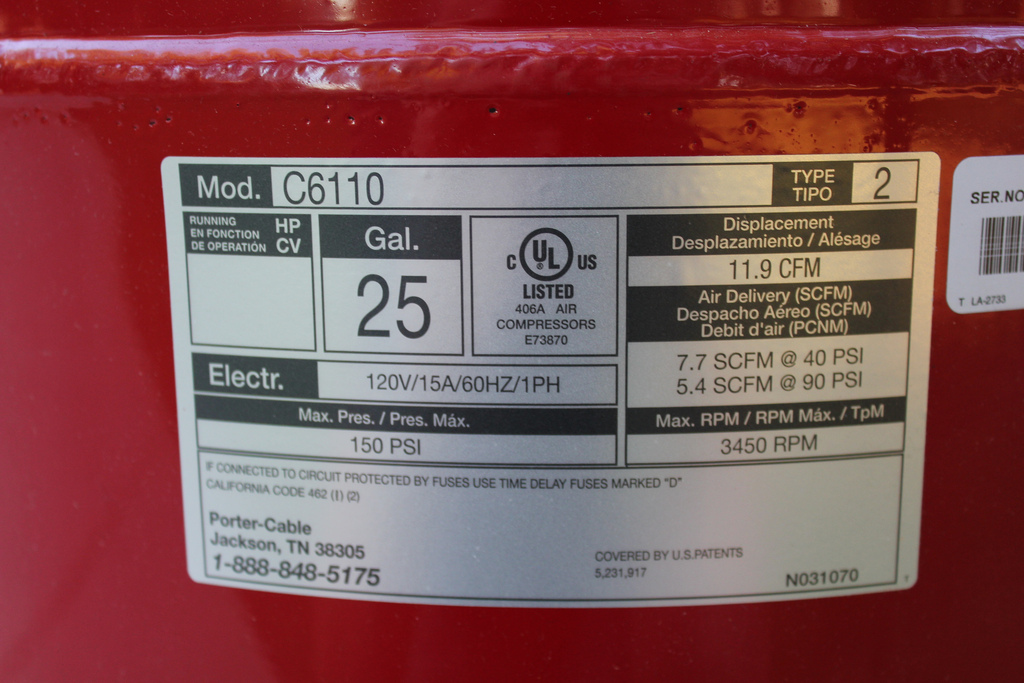

So I set off to find one just like it. I learned quite a bit about air compressors in the process. Like most products, there are a wide variety of types, brands, and uses. You will need to choose yours accordingly, but I knew that I would be mainly using mine in the garage. I knew I would be using it for filling up tires, changing wheels, and counting on it for use with air tools. Also, while I currently have a 240v outlet in my garage, I decided to look for a 120v compressor because of the universal compatibility with household outlets, and because the 240v outlet is in an awkward spot in my garage which wouldn’t allow me to park a compressor next to it.

There is also a big divide with air compressors. You can go the oiled route, in which you must maintain your compressor similarly to a car and change its oil occasionally. This will usually provide for a longer life, but you might get oil in your airflow. Oil in the air usually isn’t a problem unless you plan on using the compressor for painting. The other route is oil-free. This motor uses a special liner in the cylinder that reduces friction and wear and eliminates the need for oil to be used as a lubricant. Oil-free will last a long time, but probably not as long as a well maintained oiled compressor. I wasn’t planning on using my compressor daily, so oil-free was desirable for me. I’ve got enough toys that require oil as is, so I’m all about low maintenance.

Then there is tank size, portability, engine power, CFM, drive, and stages to consider. That’s a lot to take in. In an abbreviated nutshell:

- If you are going to need lots of air in a short time period, get a bigger tank. I advise to just get as big of a tank as you can afford for your intended use.

- If you want to use your compressor in multiple locations or keep it in your car for tires, then you’re obviously going to have to go with a portable compressor. You will lose power and CFM with a smaller compressor.

- Engine power. Be careful here. Manufacturers lie out their ass about HP on the air compressor motors. If you’re looking at a 120v air compressor that claims it has a 6HP motor (like that Craftsman 16731 my friend has) it is a complete marketing scam. You aren’t going to get more than ~2 HP from any compressor on a 120v outlet, and that’s just the way it is.

- CFM is the most important feature for me. Essentially, it is how much air will be flowing through the hose. This is very important if you plan on running air tools. Basically, you will want to look up the CFM rating on the air tools you plan on using, and get a compressor that can produce that CFM, or more. Typically these CFM ratings will be rated at 90psi, which is standard. For a 120v compressor, try to get as close to 6 CFM at 90 psi as possible. Any ratings higher than that should be questioned. If you are going to be running tools continuously, then recovery time and engine power will be important to you as well.

- There are two drives for air compressors: direct and belt. For average consumer purposes, belt drives are much quieter and more efficient, but oil-free compressors are typically direct drive.

- Then there are single-stage and dual-stage compressors. Single-stage keeps air compressed with a diaphragm, dual-stage uses one tank to compress air and one to store the compressed air. Dual-stage is usually more efficient, outputs higher PSI, and can store a PSI for longer durations.

My requirement list was formulated to this:

- 120v

- Oil-free

- >5CFM @ 90PSI

- Vertical, large tank, with wheels

The oil-free requirement really limited the selection. Most oil-free compressors aren’t vertical, nor do they have large tanks. In fact, the C6110 was the only one that I could find with decent performance and reviews. I believe the lack of selection is because the average consumer isn’t looking for a large air compressor. They don’t know any better, and companies are only going to build products that sell. If large shops are the only ones buying large compressors, and the large shops want the longevity of oiled compressors, then oil-free large compressors are going to take a hit. I think that’s what Craftsman found out a few years ago, which is why my friend’s compressor is impossible to find. It’s also why I think the C6110 is going extinct, which I will get to soon.

Receipt

Best Price (at time of writing): $419 from Tyler Tool. But it says under availability that it is “special order,” which is a red flag that they might not even have it in stock.

Best Price, Reliable (at time of writing): $435 from Amazon

The C6110 is getting harder and harder to find, so price points are going to be steady, and increase in time as supply goes down. Why do I think the supply is going to decrease? Because the C6110 is no longer on the Porter Cable website, which suggests they are no longer manufacturing or selling it. In fact, at the time of this article, Porter Cable doesn’t have a single large tank compressor on their site. Who knows what’s going on over there with the economy the way it is.

At this point of urgency, there wasn’t much for price shopping. I originally tried to order the cheapest deal I found, from PlumberSurplus.com. They took my order for $358, shipped, but didn’t tell me it was back-ordered until weeks later. Eventually, it was decided that they would not be getting any more in. Thanks a lot.

So I skipped the hassle and went with Amazon. At that time, the compressor cost me $383, shipped. Today, the compressor is $435 on Amazon, shipped.

Review

The compressor arrived in less than ideal shipping condition, so I was skeptical and bummed that I might have to go through the hassle of sending it back. Fortunately, my fears were misplaced.

I have been using the compressor for a year now, for light purposes, and it has treated me well. I have even used it with my Ingersoll Rand impact wrench, and it performs very well with it. Just as well as any other compressor I’ve used, if not better. I have not used instruments to measure airflow, but I haven’t noticed any lagging or lack of power from my impact wrench.

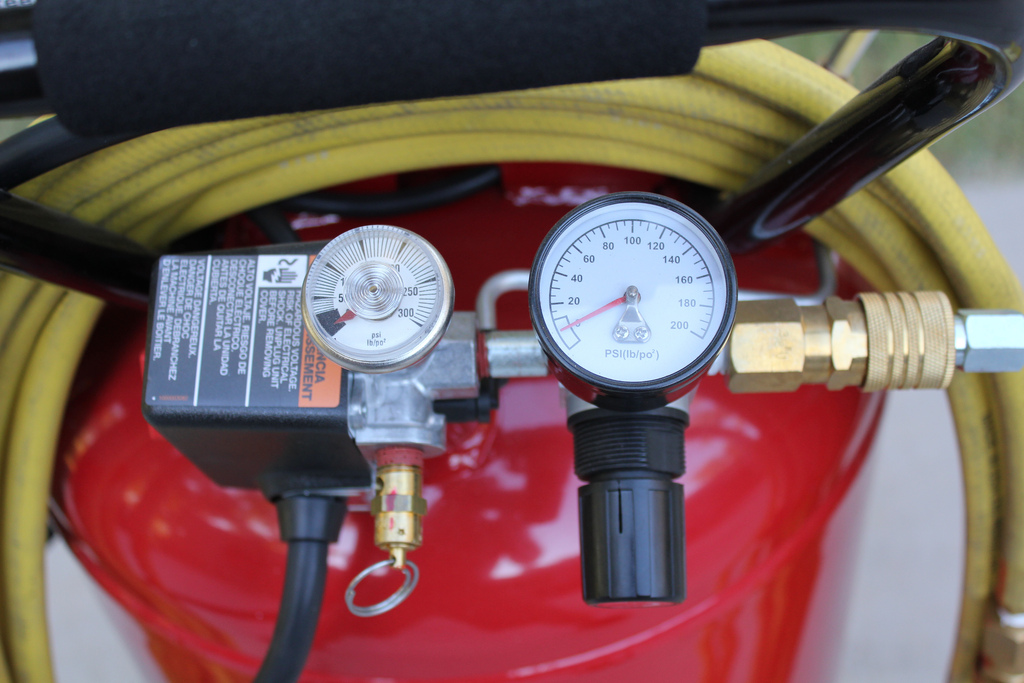

The compressor comes with a tank gauge and a pressure regulator. They both seem of average quality, but I have not noticed any leaks or problems with them. The pressure regulator came threaded a bit loose, but it hasn’t been a problem, even without adjustment.

The motor is loud, but I expected it. Most oil-free compressors will be very loud. This one is loud enough that I have to wear ear protection when it is on and I am standing by it.

I have noticed that the motor shakes a lot. It vibrates at a very high frequency, but it is not violent or unstable. It does not rattle or sound like it is falling apart, but I feel that vibration of that sort can only be problematic after years of moderate use.

The compressor does not come with a hose. Most people recommend a 3/8″ rubber hose for the ~5CFM applications, which is fine, but if you use 1/4″ couplers on the ends, I found them to be restrictive of airflow. I used 1/2″ inner-diameter couplers to allow more airflow, although it proved to be quite a bit of work to get all the compatible fittings.

All in all, I have had few problems with this compressor. The motor has an automatic shutoff limit at 150psi. I’ve noticed that if it reaches its cutoff, and you use some air, if the PSI does not decrease enough to restart the engine, the engine will not restart even if you turn the compressor off and on again. This confused me once when I turned the compressor off at ~145 PSI, and it would not turn back on. I assume there is a ‘safe PSI’ at which the compressor will resume operation. This PSI is probably around ~135, but I have not measured it.

Compressing and decompressing air in a tank causes moisture particles to compress together and become liquid on the inside of the tank. Be sure to drain the compressor after every use, otherwise, it will rust. There is a drain plug at the bottom of the tank that is for this purpose. I have noticed it can be a bit finicky. It is a drain plug that is intended to be unscrewed by hand, but it will only do this at specific PSI levels. I’ve noticed it has a sweet spot around ~30PSI. Any more and the pressure inside the tank will prevent you from unscrewing the plug. Any less PSI, and it is very difficult to turn.

Drain it after every use, and Porter Cable recommends storing it empty. Easy maintenance for this guy, which is exactly what I wanted.

Tip: make sure you have a trash towel laying under the drain though because a lot of gunk comes out. Here’s my designated drain towel after a year of compressor use:

Other than that, the compressor has performed admirably. It’s too bad that they are on the endangered list, get one while they are still around.