If you’ve been thinking about buying an AR or just started learning about ARs, there are some things you should learn about the weapon system first. In specific, the differences between consumer-grade quality, and mil-spec quality. To help, I’ve compiled a guide of information that should help you get started.

Wise up before investing serious money. Before buying any AR, read our AR Buyers Guide here.

Foreword

This guide is intended for those who are beginning to study the AR market or those who are interested in purchasing their first AR. Just like any product line, marketing is the tide of the market. People will buy what they believe in, and marketing creates a strong impression on consumers that affects their beliefs and purchasing decisions. The average consumer has confidence in buying what is deemed “the best,” what is recommended them, or what they can afford. You have arrived here either because you don’t believe everything you hear about ARs, you are meticulous about your research and purchases, or someone you know cares about you enough to attempt to rehabilitate your marketing-induced impressions of ARs. I, the compiler of this document, am categorized in the second classification.

I originally researched ARs for several months before deciding on what I wanted. I am the type of person that completely immerses himself in readings, research, data points, specifications, reviews, and reputations before buying a product that I intend to expect nothing but the best from. This doesn’t necessarily extend to everything I buy, but if it is something that I intend to stake my life on (realistically or metaphorically), then I will put in the time to find the best product for the money.

This guide was created because the AR market is exceptionally deceptive. I have never compiled a guide like this before because I have never been deceived by marketing as badly as I was in my own AR research. In my own research, I was certain I had narrowed down the selection to what constituted as high-quality AR systems. Cutting to the chase, I had not. It turns out there are two avenues of which to pursue in the AR market: consumer-grade and military-grade. As it turned out, I had unknowingly been researching consumer-grade ARs. In a way, the military-grade AR market is buried underneath all the marketing, claims, and consumer-grade ARs.

The purpose of this guide is to concisely focus on the advantages of the military-grade (Mil-Spec) AR. There are many benefits that can come from getting a military-grade AR. This guide will help you sort through what the differences are between the two gradations.

Before reading this guide, you must understand that consumer-grade ARs can still be very reliable weapon systems. Just because an AR isn’t meeting some or all of the military’s specifications, does NOT imply that the AR will perform unsatisfactorily. On the contrary, most ARs available on the civilian market are consumer-grade, and perform extremely well, if not flawlessly, when maintained and used properly. It is not the intention of myself, nor this guide, to suggest that consumer-grade ARs are inferior in every way. Rather, Mil-Spec ARs will consistently maintain higher quality standards, quality control, and quality materials. The advantage of owning a Mil-Spec AR is the confidence gained from owning a rifle that is built to be abused and be reliable in every way.

So please, don’t use this guide as an end-all reference, but as a way to expand your knowledge about ARs in general. Beyond learning about Mil-Spec ARs, this guide will teach you about ARs in their entirety, and what to look for on any AR to determine if it is of quality.

The information contained here within is the property of its cited author. I do not claim this information as my own intellectual property.

Introduction

The following was written by “Haji” on Apr 01, 2011. The original content is located on the Knob Creek Range forum.

There are a few factors to consider when purchasing an AR. In this economy, the first thing to decide is how much of a budget you have, and to get the best gun you can within your budget. That amount of funding can be augmented by being open to trades or selected used components such as fore ends or buttstocks.

There are two types of AR’s: commercial spec guns like Bushamster, DPMS, Rock River and some others. The other type are duty quality, Mil Spec guns like Colt, Bravo Company Manufacturing (BCM), and Daniel Defense, among others. Essentially, duty quality weapons are built to a standard. Most adhere as closely as possible to the Technical Data Package (TDP), which is the actual Mil Spec standard that Colt and FN build guns for the military to. Commercial spec guns aren’t built to a standard, and as such are usually lacking in attention to detail in important areas. Among these are the staking of the carrier key screws, staking the castle nut, and torquing the barrel nut to the spec. Additionally, the quality of the parts (springs, pins, hammers, etc) are not the same as the quality of Mil Spec parts, because commercial spec guns don’t have the same standard.

Why does this matter? Because what’s happening when a gun is fired is rather violent. Parts wear against each other, and screws and nuts work loose. When that happens, your gun goes down. If you’re lucky, all that’s lost is some time at the range. If you’re unlucky, it could be a whole lot worse than that. as the gun has failed when you need it most.

Mil Spec guns will generally cost more up front; remember “get what you pay for”? However, what to look for is the best value, not the lowest price. In terms of best value, the top dog is probably BCM, followed closely by Daniel Defense and Colt. There are several levels of guns available here, running from very simple rifles with detachable carry handles and the ol’ round hand guards up through rifles with 12″ rails, tactical lights and optics. What most people typically do is to buy the “basic” carbine and swap out parts as budget and needs (or wants; that’s perfectly valid, too) allow. The only downside to that is that you typically spend a little more in the long run, and you end up with extra parts that you don’t use. The upside is that those parts end up in your trade pile, or you may use them again to complete another rifle built around a stripped lower or whatever.

You can save a little money if you buy the upper and lower separately; a complete gun is subject to an 11% federal excise tax. Some companies, such as BCM, occasionally sell blemished or “blem-ed” parts, particularly lowers. The shop I work at transferred a couple of them for one of our friends, and we were hard pressed to find definitively what the blemish was. A cosmetic blemish is not a big deal, especially from a good source like BCM. A mechanical blem is something else entirely; that means the important part of the lower-where the holes and such are drilled-are wrong and the rifle is going to be a problem until it’s been fixed. That’s a major reason to stick with name brands. A Mil Spec blem lower can go for as little as $250-$300. Buy a quality upper (if you have to choose where to “put the most money”, put it in the upper; it’s more important. The lower is a pretty low stress part) and push two pins together, and you have a heck of a gun for the money.

Don’t get too tied up in “fit and finish”. How well an upper and lower match in color has a lot less to do with performance than quality parts made to a standard do.

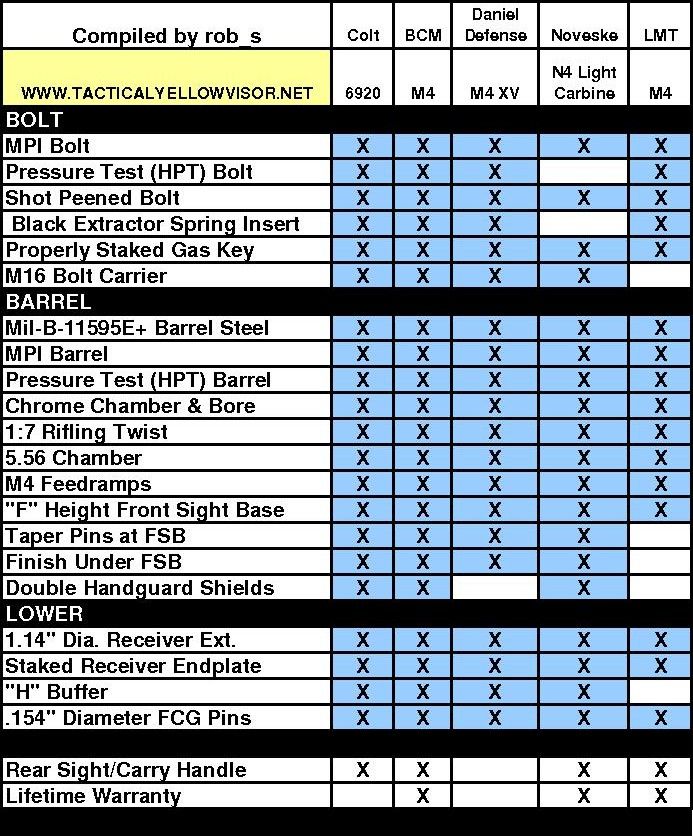

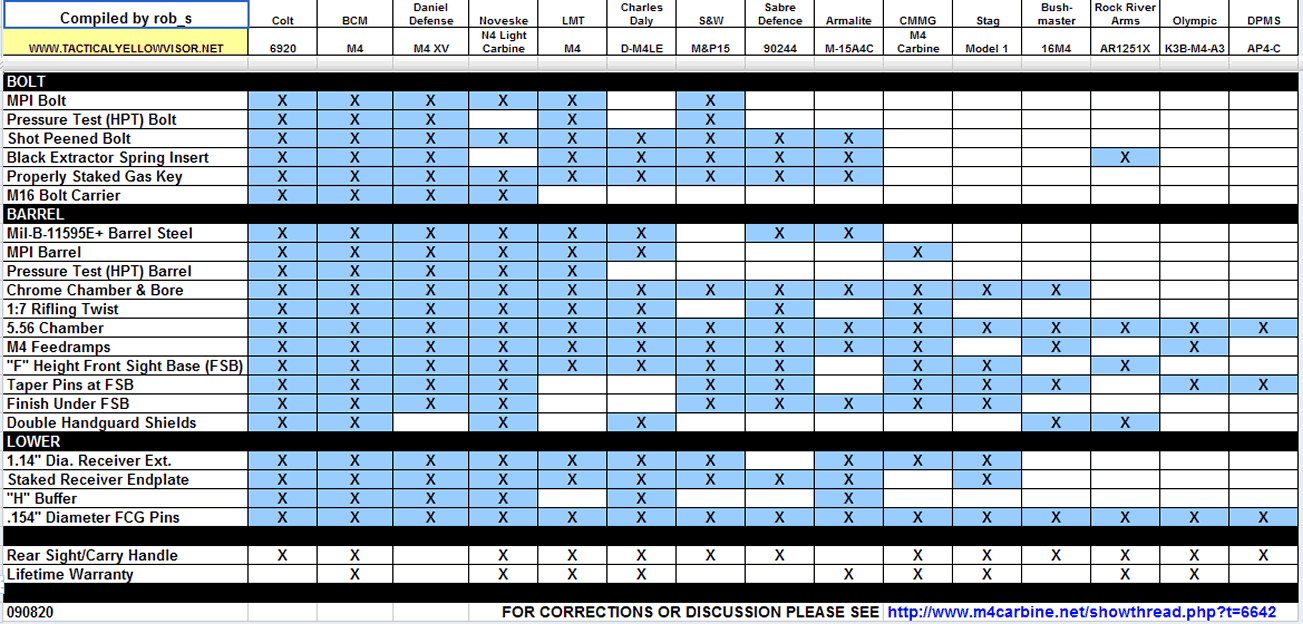

To help with comparing some of the available rifles and what you get for the money, Rob Sloyer has put together what’s become known as The Chart. It is not comprehensive, but it is representative. When viewing the chart, make sure you read the explanations of what the entries on the chart mean, so you can have an understanding not only of the differences, but what the differences mean and why they’re important. There’s a thread dedicated to The Chart on M4carbine.net… (omitted – covered later in this guide)

I don’t mean to overwhelm you to answer your question; rather, I’m trying to answer your question in such a way that you get the most gun for your money. Choose wisely and you’ll have a trouble-free, great performer that will last you and your kids a lifetime and then some.

– User “Haji” on the Knob Creek Range forum

Ways That Consumer Grade Rifles Might Cut Corners

The following was written by Bartholomew Roberts on Dec 26, 2006. The original content is located on The High Road forum.

Ever wonder why a Colt LE6920 sells for over $1k while an Olympic Plinker sells for under $600 on occasion? One reason is that there are dozens of places to change parts away from the specifications military contractors must provide to cheaper parts and practices that may not be necessary for commercial ARs. Not all of these changes are bad. Many of them will never be noticed by 99% of shooters; but some of them can effect function and I think it is important that a buyer understand what type of trade they are making when purchasing a rifle.

For an easy to follow shorthand, I’ve set up the following reference system (reflecting only my own opinions):

* Most likely will not make a difference for all but the most demanding shooters who put their rifles to hard use.

** Unlikely to make a difference for the vast majority of recreational shooters, may see occasional issues among those who train frequently.

*** Known to effect reliability for all users, though it may still not be an issue if you don’t shoot that much.

1. Use cheap extruded or cast charging handle instead of proper forged charging handle.**

2. Cheap shot-filled or plastic buffer instead of correct military rifle or carbine buffer.***

3. 4140 barrel steel instead of 4150 MIL-B-11595.*

4. Don’t proof test the barrel or bolt.*

5. No need for magnetic particle inspection of barrel or bolt.*

6. Don’t test-fire the rifle prior to selling it.***

7. Replace heat-shielded handguard with lower grade plastic and no heat shield handguards.**

8. Use the same front sight base for every model instead of F-marked front sight base for flattops.*

9. Cast front sight base instead of forged.*

10. Cast upper and lower receivers.**

11. Plastic upper and lower receivers.**

12. Have a bunch of uppers that don’t quite meet the Picatinny spec? We’ll take them at a discount!**

13. Torquing and staking the gas key is something the customer can do.***

14. No chrome-lining.*

15. Why buy chrome-silicon springs designed for the weapon when we can use a cheaper steel and cut them to fit?***

16. That part is only a little out of spec. We can make it work with a little grinding and save money on parts too!***

17. Why use trained monkeys for assembly when regular monkeys work for half and can do the job almost as well?***

18. Make so many exceptions to your “lifetime warranty” that it will be impossible for anyone to ever make a valid claim against your “warranty.”

19. Nobody will ever notice a few .001″ difference on that part.**

20. Our patented spray-paint finish is much better than anodizing.**

21. Shipping every rifle with an HBAR profile to save machining costs, even if it is an entry rifle/”lightweight” carbine.*

22. Replace metal parts with plastic -plastic magazine release, trigger guard or delta ring.**

23. Use an Unmarked/mismarked A2 Elevation Adjustment Knob for the rear sight.**

24. Plastic A2 trapdoors in the butt of the rifle stock.**

25. Replace forged AR15 hammer with cast hammer.**

26. No drain hole in stock screw.**

27. Dremel cut feed ramps instead of feed ramps cut prior to anodizing.***

28. Use cheaper cast/extruded receiver extension instead of military extension (different diameter also).**

29. No parkerizing under the FSB.*

30. Straight pins or even roll pins instead of taper pins in FSB.***

31. Using A2 windage drums on detachable carry handles.**

32. Don’t mark the barrel with chambering or twist rate.**

33. Don’t stake the castle nut in place.**

34. Don’t shot-peen the bolt during manufacturing.*Note that there is often disagreement about how crucial some of these issues are and likely people will disagree with some of the arbitrary judgements I’ve made just to simplify it for those who don’t want to read through a discussion on each of the 34 points. Also note that you can often learn more about any one of these subjects using a quick search in the rifle forum.

Thanks to the members of AR15.com who helped me flesh out and condense this list.

– Bartholomew Roberts on The High Road forum

What Does It All Mean?

Written by “fubar214” on Aug 5, 2009. Original content is located on Gun Forums.

Bolt and Bolt Carrier

The bolt carrier group (BCG) is the heart of the AR-15. It chambers and extracts live and spent rounds. A failure on either end of the feeding process with result in some sort of stoppage from minor to catastrophic. Having a truly milspec bolt carrier group is essential to any rifle intended to be used as a defensive weapon. In a defensive situation, a jam can result in death.

High Pressure Test (HPT)

Pressuring testing the bolt and barrel is a way of finding any defects in the parts while still at the factory, and not leaving it for YOU to discover the hard way. Most manufacturers batch test their barrels and bolts. In other words if 50 rifles were produced in a group, they would test ONE rifle for defects. Most likely, the rifle they test won’t wind up being YOUR rifle, which really gives you no assurance. A guarantee or lifetime warranty is fine if your rifle poops out on the range, but in a defensive situation it does you no justice. Buy a bolt that will work the first time, everytime.

Magnetic Particle Inspection (MPI)

MPI inspections are a second line of defense in assuring no faulty products leave the factory. After doing the HPT test, the part in question is subjected to MPI testing to ensure there are no microscopic hairline cracks in the metal. Just like HPT testing, most manufacturers batch test their rifles and some don’t even do it at all.

Shot Peened Bolt

Shot peening is the best method in which to construct a bolt, it is simply stronger at the molecular level. Shot peening provides superior resistance to metal fatigue than other methods of production. This is crucial in sustaining service life and reliability over the lifetime of your bolt. Anything other than a shot peened bolt is NOT milspec.

Properly Staked Gas Key

The gas key is a critical component of the bolt carrier. If the gas key fails, your rifle is literally turned into a single shot, manually cycled weapon. I’ve witnessed this firsthand with my Olympic AR-15. The allen screws loosened up in the gas key because they weren’t staked at the factory. There aren’t many companies that completely disregard staking, but Olympic is one of them.

It is important to know however, the most companies don’t stake their gas keys PROPERLY. Stag, CMMG, Armalite, DPMS among many others do a very poor job at staking the gas key, which leads many people to believe they are doing it for show. An improperly staked gas key might as well not be staked at all. A properly staked gas key will NOT allow the allen screws to walk out under any circumstance. The three companies that supply to the military all have properly staked gas keys. All other manufacturers are lacking in this department which IS a big deal. This is one of the reasons I highly recommend LMT BCG’s.

Barrels and Chambers

Here are a few things to keep in mind. Number one, .223 Remington and 5.56x45mm NATO are NOT the same round. Number two, selecting a proper twist rate IS important. Number three, there IS a difference in the grades of barrel steel.

HPT and MPI Testing

Barrels undergo the same testing as bolts. See ‘bolts’ above for a more detailed explanation.

Milspec Barrel Steel

Many manufacturers claim to use milspec barrel steel, when in reality most don’t. The military standard is MIL-B-11595E. Most manufacturers write off 4150 and 4140 as military grade barrel steel. The composition of barrel steel is important in more than one way. As the barrel heats up during sustained firing, accuracy decreases. True milspec barrel steel is the most heat resistant barrel steel available and will keep groups tighter under higher temperatures than inferior barrel steel. Milspec barrel steel will also increase the service life of your barrel. In order of performance from best to worst, MIL-B-11595E, 4150 and finally 4140.

Chrome Lined Barrel and Chamber

A more detailed explanation on chrome lining.

Milspec Chamber

This is the same link in which I discuss chrome lining.

Twist Rate

Different bullet weights and lengths perform better in barrels with ideal twist rates. Generally speaking, selecting a proper twist rate is imperative for optimal accuracy and safety. This is a lengthy discussion and is already underway in another topic elsewhere on the forum. I will link to that topic rather than elaborate.

M4 Feedramps

There are two types of feed ramps, rifle and carbine. M4 feedramps aid in feeding ‘oddball’ bullet styles better than standard rifle feedramps. For example they will increase reliability when using longer bullets, such as the 70gr+ match rounds and other bullet styles such as soft points. M4 feedramps don’t decrease feeding reliability when using standard ball, regardless of whether the rifle in question is long or short barreled. M4 feedramps promote increased feeding in all rifles, regardless of what rounds you are using.

Buffer Assembly

Since the buffer assembly works in conjunction with the bolt carrier group, it is vital to rifle reliability. The buffer is one half of the equation in ensuring proper timing in your rifle, which in turn leads to proper function.

Properly Staked Receiver Endplate/Castle Nut

In AR-15 rifles, when the BCG travels rearward resistance is placed upon it by a buffer assembly. The buffer ‘bounces’ the BCG forward and back into battery. The buffer assembly and bolt carrier in conjunction control the lock time of the rifle. The buffer is weighted and is held under tension by the buffer spring, which is held in place by the buffer retaining pin and receiver extension. The castle nut is what prevents the receiver extension from backing out during firing. If the receiver endplate isn’t properly staked and the castle nut loosens up during firing, you’re in trouble. The entire buffer mechanism can be compromised and turn your rifle into a paper weight. I’ve also seen this malfunction firsthand.

Other

Things that would fall under other aren’t really differences that affect rifle performance. They are more personal preference/cosmetic differences. Right now there is only one worth mentioning, but possibly more content could be added to this section in the future.

Parkerizing Under FSB

This is a cosmetic and/or personal preference feature. Some of you may be surprised to know that the overwhelming majority of AR-15 manufacturers don’t parkerize under the front sight base. Once the FSB is attached to the barrel, they then parkerize the entire assembly, leaving the barrel underneath the FSB uncoated. While this doesn’t really affect the function of the firearm, it can cause your barrel to rust where the metal is unprotected.

User “fubar214” on Gun Forums

Chart of Specifications to Look for in an Authentic Mil-Spec AR

Written by Rob Sloyer and updated on Jun 10, 2011. Originally sourced from Rob’s Google Sheet.

Which Companies Adhere to Mil-Specs, A Comparison Chart

Written by Rob Sloyer and updated on Jun 10, 2011. Originally sourced from Rob’s Google Sheet.

Expansion: Impressions and Advice from an Experienced AR User

Summary of an in-person conversation with Brian P. on Oct 20, 2011.

- Good Companies: Colt, Bravo, LMT, CMMG, RRA, Sabre ($), Knight ($), Noveske ($)

- Bad Companies: DPMS, Bushmaster

- Bravo Company USA makes the best Mil-Spec AR for the money

- LaRue rails are ideal

- Gas tubes are classified as:

- “Carbine” gas is 7” tube (bad)

- “Midlength” gas is 9” tube (great)

- “Rifle” gas is 12” tube (better, but longer barrel)

- The longer the gas tube the better (smoother action, less heat, less pressure), but the trade-off is barrel/rifle length.

- Lower receiver assembly diagrams on AR15.com

- The only part that needs to go through an FFL is the stripped lower receiver (the part where the magazine is inserted). Everything else can be purchased online and shipped to your home.

- You can get discounted parts that have cosmetic blemishes. These defects don’t affect performance, and are called “Blems.”

- To save some money, you can buy the lower receiver disassembled, and assemble it yourself. The lower receiver without the internals is called a ‘stripped lower receiver,’ and the bag of internals is called a Lower Parts Kits (LPK). However pre-assembled LPKs will be fitted first to ensure a good fit, which is a guarantee that your lower will work (as opposed to receiving the wrong part in an LPK).

- The stock sits on a buffer tube. The buffer tube houses a spring and a ‘buffer.’ The buffer is what the bolt cycles into as the gun is fired. The buffer is a weight, that determines how fast the bolt returns. Buffer weights are as follows:

- Standard, lightest, fastest pulse

- H, most recommended

- H2

- H3, heaviest, slowest pulse

- For .223/5.56, Mil-Spec M193 (55 gr.) & M855 (62 gr.) ammunition is best. Lake City makes it Mil-Spec, Federal brands it for the public as XM193

- Troy for BUIS are ideal

- VLTOR EMOD Stocks are great and have ideal sling mounting positions

- For current ammo prices, go to gun-deals.com